Giving sight to the blind (connection)

You are visiting the United Arab Emirates Kee Safety website from United States. Would you like to go to the United States site?

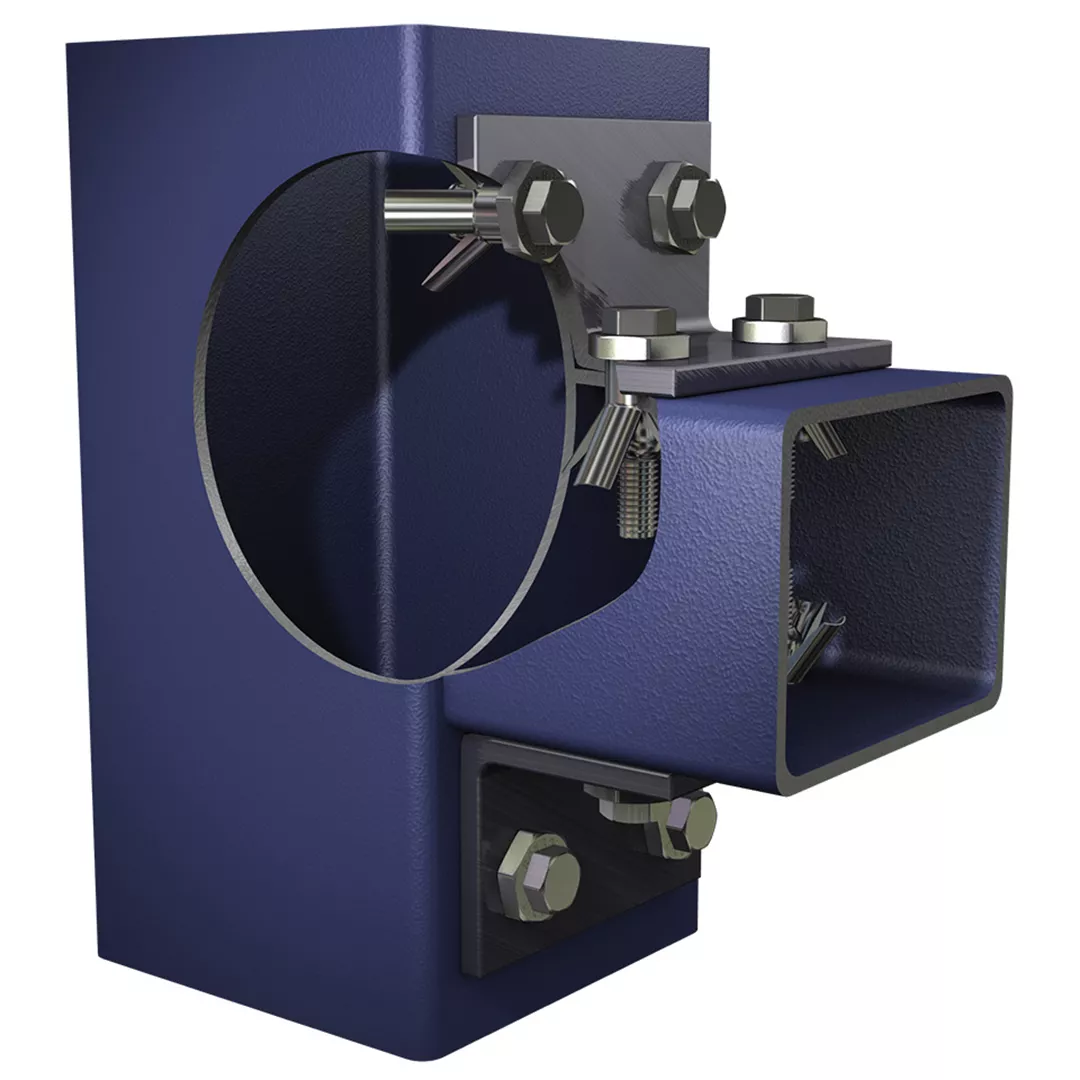

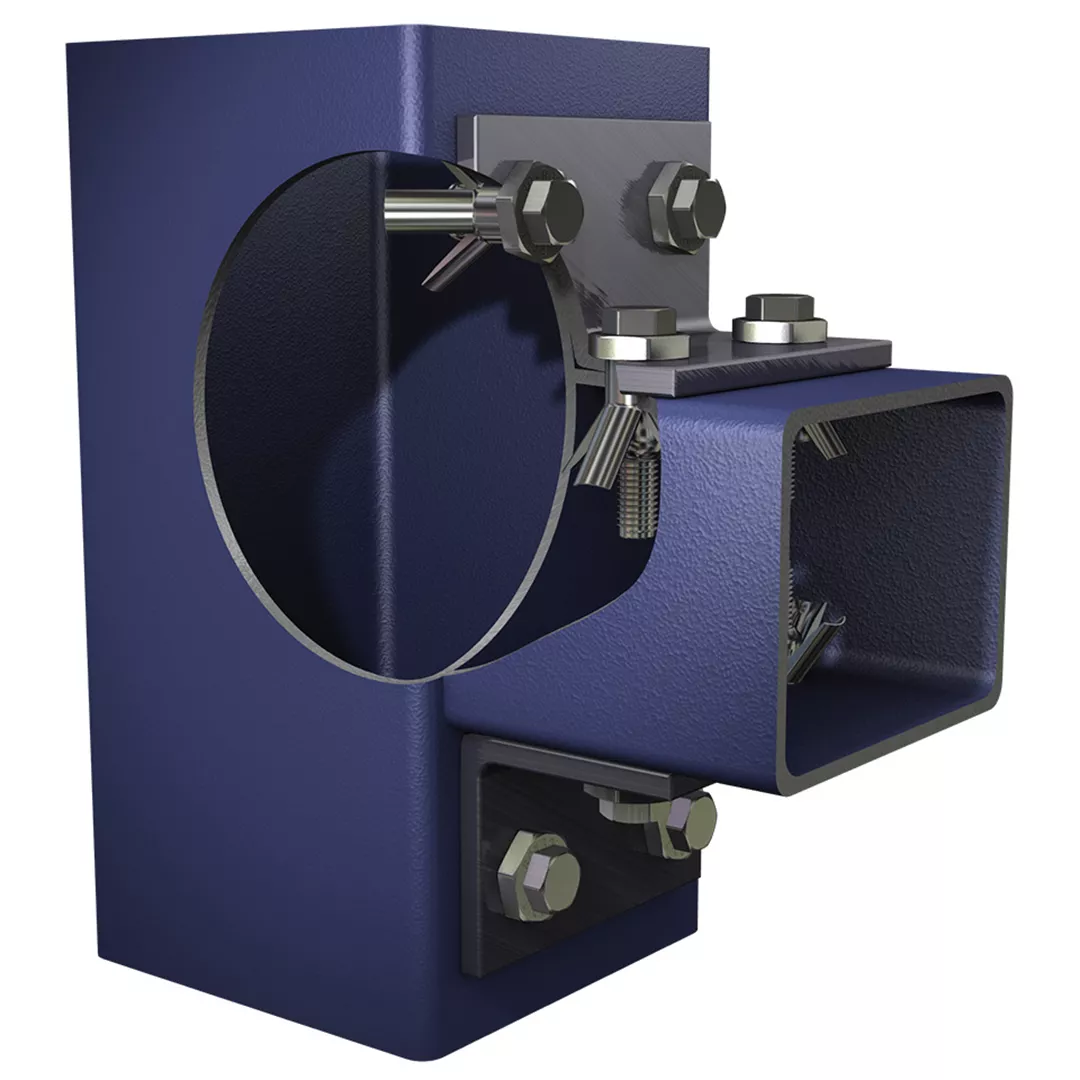

With no special tools or installation skills required, BoxBolt can deliver savings in both time and cost on-site.

BoxBolt is CE certified and approved for use by Lloyds Register (LR) type approval.

BoxBolt components are available in three finishes: zinc plated, galvanised and stainless steel, for long term corrosion resistance in any environment.

Fewer BoxBolt fixings are required to make shear connections, offering greater design flexibility and potential cost reductions.

A wide range of BoxBolt sizes is available to suit the thickness of the steelwork being connected. Special lengths are also offered for non-standard applications. BoxBolt connections are available in three finishes: zinc plated, galvanised, and stainless steel.

Approved for use by Lloyds Register.

Complies with the DIN 18800 and Eurocode 3 design methods for bolted steel connections.

CE certified in compliance with Regulation 305/2011/EU of the European Parliament and the Council of 9 March 2011 (the Construction Products Regulation or CPR).

The BoxBolt Type C is physically tested with International Accreditation Service certification, which guarantees load value with the correct torque applied, as stated in the Measurements and Specifications.

ICC ESR-3217 – BoxBolt is the first blind fastener to achieve ICC Testing and Approval.

Acceptance Criteria AC437 – This means all aspects of blind bolting are covered, and the product is safe to use for all blind connections.

We offer a full engineering service to support our products, from providing assistance with component selection to a full design capability for large projects.

| Document | Format |

|---|---|

| Safe Steelwork Fixings Brochure | |

| BoxBolt ETA Certificate | |

| BoxBolt Declaration of Performance | |

| BoxBolt Data Sheet |

| Document | Format |

|---|---|

| Safe Steelwork Fixings Brochure |

| Document | Format |

|---|---|

| BoxBolt ETA Certificate | |

| BoxBolt Declaration of Performance |

| Document | Format |

|---|---|

| BoxBolt Data Sheet |

Please fill in your details below and we’ll be in touch shortly.