A heavyweight in being lite

You are visiting the United Arab Emirates Kee Safety website from United States. Would you like to go to the United States site?

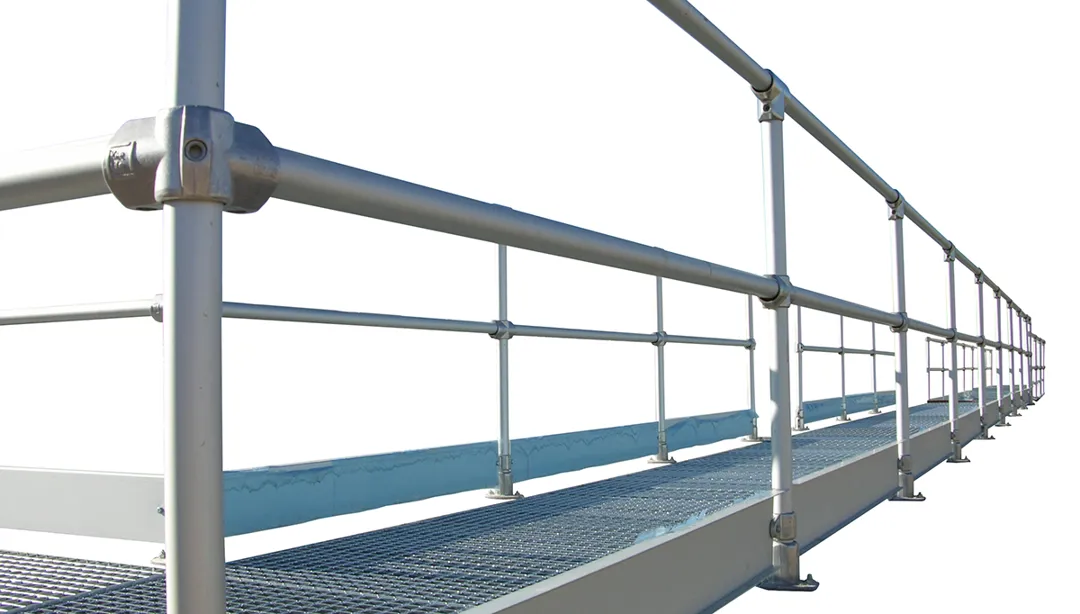

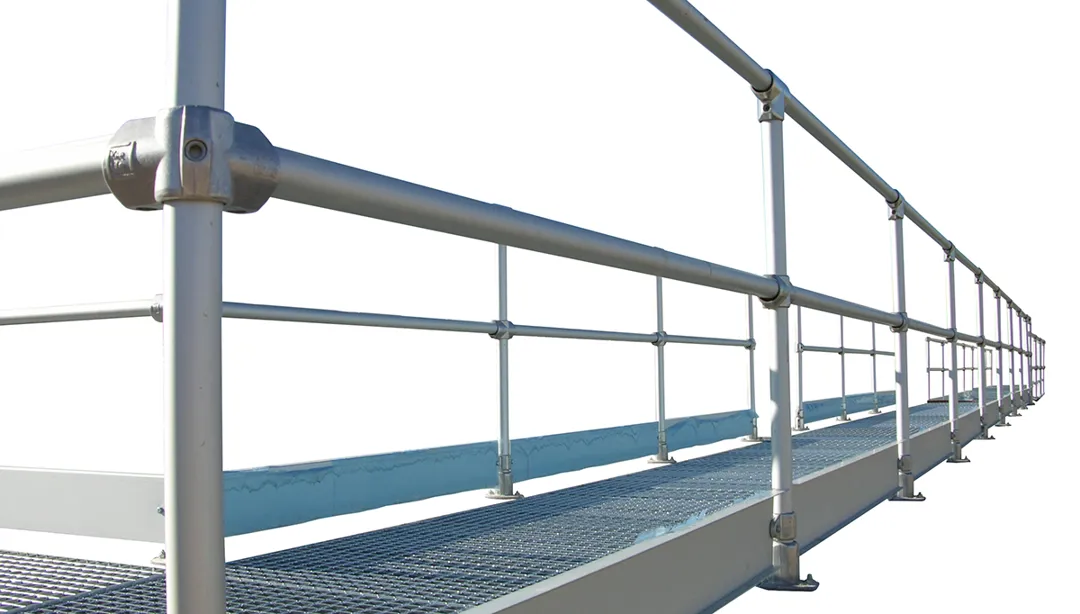

A lightweight, weld-free system for creating handrails, safety barriers and guardrail systems that exceed EN and OSHA safety standards.

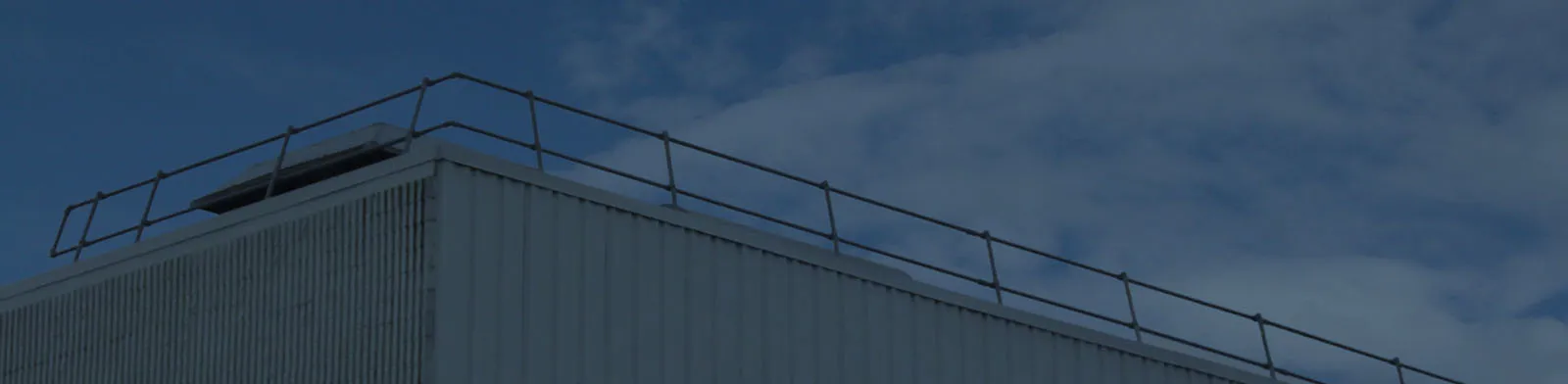

Anodised aluminium is corrosion resistant and wear-resistant

Made from high-grade aluminium silicon magnesium alloy

Lightweight design for maximum versatility and flexibility

Large fittings range ensures you can meet any on-site situation

Kee Lite fittings are designed to stand the test of time in harsh environments. Kee Lite components have been used for decades in surroundings like the deserts of the Middle East or the shores of Great Britian. Trust the reliability of your safety solution to a product that has been tried and tested.

Kee Lite aluminum fittings are the foundation of all Kee Lite safety railings. In addition to railings, they can be used to assemble endless structures. Enjoy the lightweight of aluminium and the flexibility of building with fittings. Find out more about our complete range of aluminum components.

Kee Safety runs one of the world’s leading test and training centers at its UK headquarters. Run by a team of industry experts, this state-of-the-art facility ensures that Kee Safety products meet the needs of its customers. Kee Safety is committed to driving new innovation with the purpose of separating people from hazards.

We offer full design and installation services that include a complete on-site survey. Also, we can produce comprehensive shop drawings to help you visualise the end result. With our detailed project outline, you can be confident that your project is professionally specified, and that all safety concerns and standards are addressed to your satisfaction.

Alternatively, you can specify and install most of our safety systems yourself with our easy-to-follow instructions – it all starts with a call to our knowledgeable staff!

Please fill in your details below and we’ll be in touch shortly.